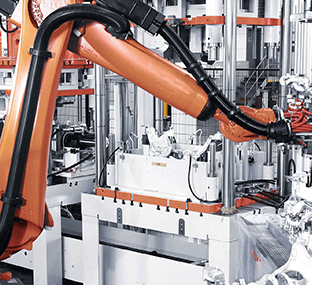

Die Casting

Horibont's die-casting is a precision casting method that uses high pressure to force metal melt pressure into a complex-shaped metal mold.

The die casting machine can be divided into two different types of hot chamber die casting and cold chamber die casting:

Hot chamber die casting

The die-cast metal pool contains molten liquid and semi-liquid metals. These metals fill the mold under pressure. At the beginning of the cycle, the piston of the machine is in a contracted state, and then the molten metal can fill the goose neck position. The pneumatic or hydraulic piston squeezes the metal and fills it into the mold.

Cold chamber die casting

When die casting cannot be used for metals in the hot chamber die casting process, cold chamber die casting can be used, including aluminum, magnesium, and zinc alloys with high aluminum content. In this process, the metal needs to be melted in a separate crucible. A certain amount of molten metal is then transferred to an unheated injection chamber or injection nozzle. By hydraulic or mechanical pressure, these metals are injected into the mold

Advantages of Die Casting

Simple or complex shapes

Thin wall thickness

Light weight

High rates of production

Corrosion resistance

Monolithic-multiple functions in one

Efficient and economical alternative to other processes

Applications of Die Casting

Components created by die casting are central in numerous industries. Examples of compatible applications include:

Agricultural machinery

Machine tool

Electronics

Security industry

3C communication industry

Medical instruments

Clocks

Camera

Daily hardware

Auto spare parts

Furniture components

Lighting parts

Toys

Construction hardware

High-speed rail

Our service

OEM, ODM customized service factory.

According to the design concept of customers, we provide one-stop service for structural design, components processing, surface treatment , assembly and delivery

Completion time of mould:

Zinc alloy mould: 15 working days,

Aluminum alloy mould: 20 working days

Magnesium alloy die and aluminum extrusion die: 25 days working days

The annual production of die-casting on ten million pieces, 100 kinds of metal technology.

Surface treatment

Horibont company carries out surface polishing treatment for products, and cooperates with many excellent surface treatment suppliers, which can be passivated (including phosphating, chromizing and coating), conductive oxidation, anodizing, electroplating, painting, powder spraying, electrophoresis, sandblasting, shot blasting, bushing and etching.

Environmental protection regulations:

Comply with ROHS, REACH, halogen-free requirements, and FDA, LFGB French / Italian / German requirements for food-grade contact.

Precision Die casting for All Chances

if you would like to know more about Horibont Industries and how we can assist you with your next project please contact us.