CNC Machining Services- Typical Products

CNC machining of parts is a subtractive manufacturing process that uses machine tools to remove portions of material from a workpiece until the desired shape is formed. The CNC machine program controls the order in which the CNC machines move around each other to produce these parts. There are many different types of CNC machine tools, including multi-axis CNC milling machines (3-axis, 4-axis, and 5-axis), CNC lathes, and turn-milling composite. While they both rely on a set of instructions from a program to perform a task, they do so in slightly different ways.

For example, a CNC milling machine keeps the workpiece motionless while rotating it while cutting the part; CNC lathes keep the cutting tools still while they work the parts they rotate.

General machine tools are developed according to their respective functions such as turning, milling, and drilling. The turn-milling complex machining equipment with the correct choice of cutting tools, and with the B axis that enables the tool to rotate and move, an advanced control system and cutting-edge CAM software, the use of rotating tools such as the clamping milling cutter or drill tool can be integrated for CNC turning to process, In this way, by reducing the number of clamping parts so that the workpiece through a clamping can complete the main processing tasks and from one machine to another machine tool times, reducing downtime and increasing machining efficiency. It not only solves the processing problem but also greatly improves production efficiency.

CNC machines have a wide range of capabilities and can produce high-precision machining parts. For example, CNC milling machines are excellent for creating cavities, shaping angled components, drilling holes, and cutting slots.

In contrast, CNC lathes are better suited for making cylindrical objects or parts that have symmetrical features around an axis.

Both types of CNC machines can achieve tolerances as tight as ±0.005mm, which also work with a variety of materials, including metals and plastics, provided these materials come in block form, bar and tube. This is not the case with additive manufacturing technologies (like 3D printing), which are only compatible with plastics and a few metals.

At Horibont, we pride ourselves on providing high-quality and reliable products. We have a team of skilled engineers and machinists who use the latest software and technology to produce precision parts that meet industry standards.

In addition, Our quality control experts ensure that each batch of parts delivered is high-quality.

Horibont offers a broad range of material options to choose from, including metals (such as aluminum, steel, stainless steel, brass, and copper), plastics (such as POM, PTFE, PC, PEEK, PET, and Nylon), and special alloys (such as aluminum alloy, alloy steel, Titanium alloy).

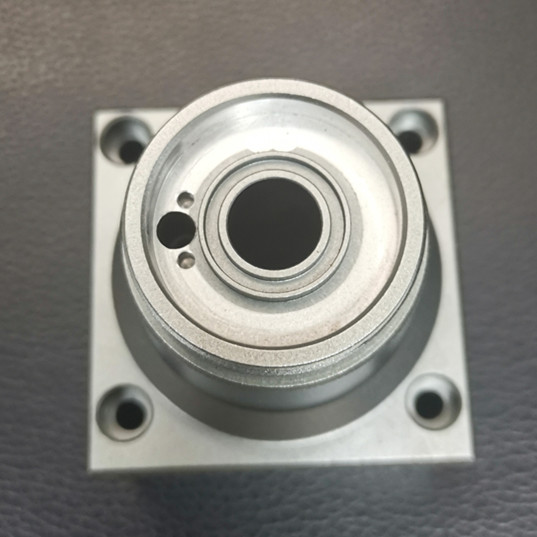

Laser Cutting Head

Material: Aluminum 6061-T

Application: Laser equipment

Description:

Tolerance: ±0.02mm

Surface Treatment: Clear Anodized

Main Process: Turning ,Drilling ,Milling Service

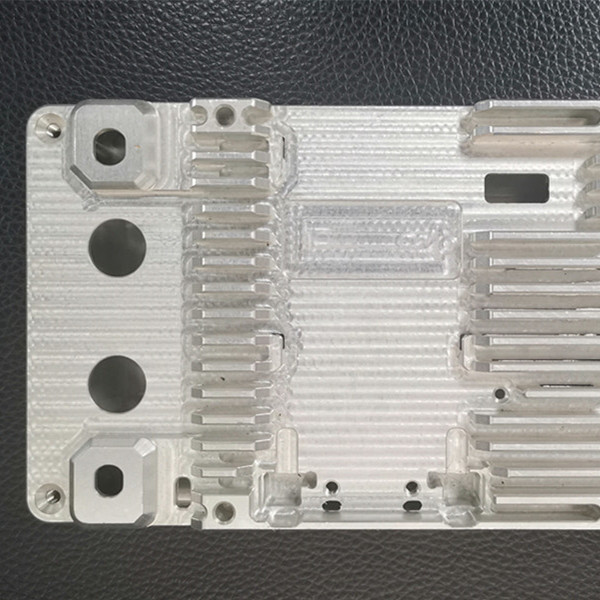

Police Device Parts

Material: AL 6061-T

Application: Police device

Description:

Tolerance: ±0.01mm

Surface Treatment: Clear /Black Anodized

Main Process: Milling Service

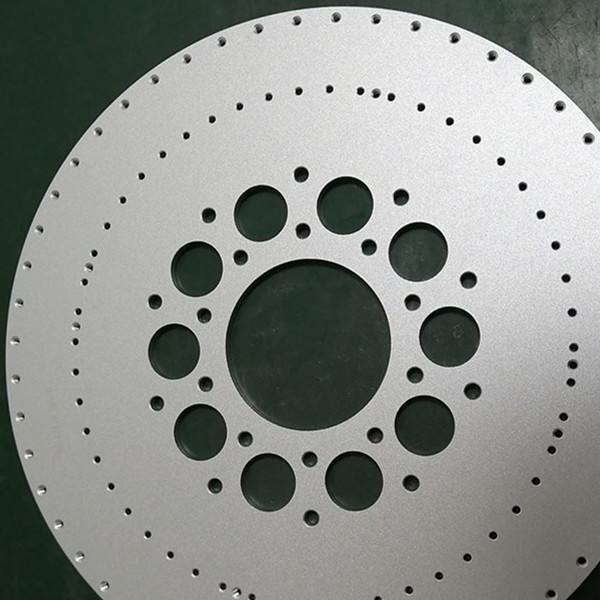

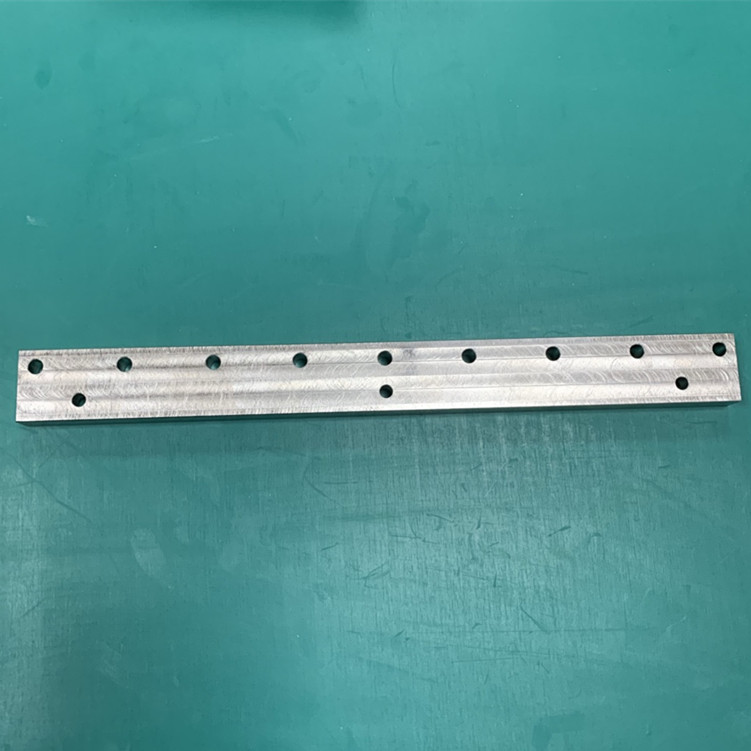

Packing machine parts

Material: Aluminum 6061-T

Application: Packing machine

Description:

Tolerance: ±0.05mm

Surface Treatment: Clear Anodized

Main Process: CNC Machining ,Turning ,Drilling Service

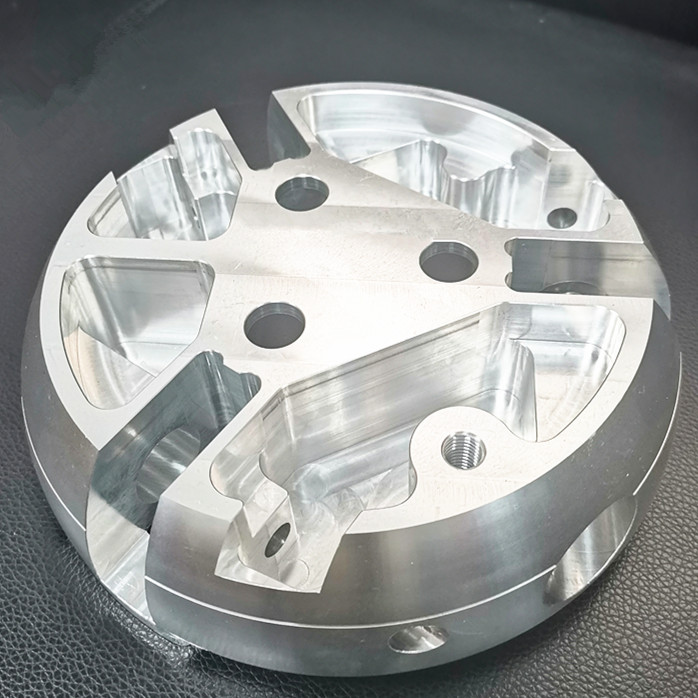

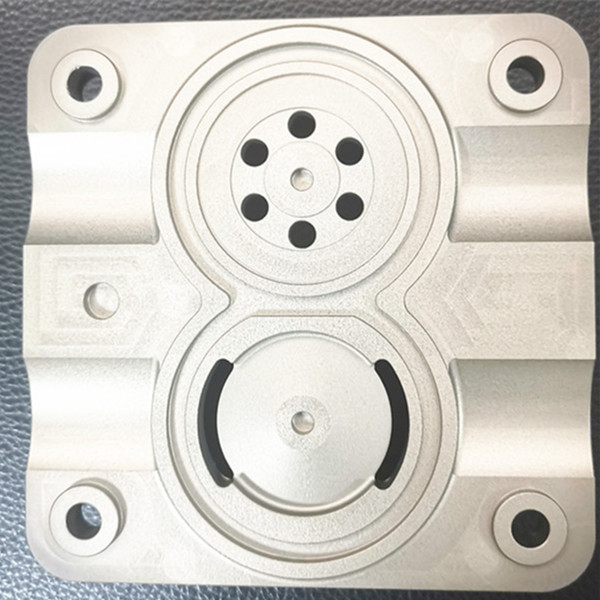

Diving device

Material: Aluminum 6061-T

Application: Diving

Description:

Tolerance: ±0.02mm

Surface Treatment: Clear Anodized

Main Process: CNC Machining ,Turning ,Drilling Service

Machining Parts-Timing Pulley Shaft,Conveyor

Material: 4140 Steel

Application: Laser equipment

Description:

Tolerance: ±0.01mm

Surface Treatment: Nickel Plating

Main Process: Turning

Machining Parts-Timing Pulley Shaft,Conveyor

Material: 4140 Steel

Application: Laser equipment

Description:

Tolerance: ±0.01mm

Surface Treatment: Nickel Plating

Main Process: Turning

Electronic cigarette equipment spare parts

Material: 1045/CRS45/4140

Application: Electronic cigarette equipment

Description:

Tolerance: ±0.05mm

Surface Treatment: Nickel Plating

Main Process: CNC machining service

Motorcycle cylinder

Material: 7075

Application: Motorcycle

Description:

Tolerance: ±0.02mm

Surface Treatment: Clear Anodized

Main Process: CNC Machining Service

CNC Machining Parts-Motorcycle cylinder

Material: Aluminum 6061-T/7075

Application: Motorcycle

Description:

Accuracy: True position 0.03mm

Surface Treatment: Hard Anodized

Main Process: CNC Turning Service

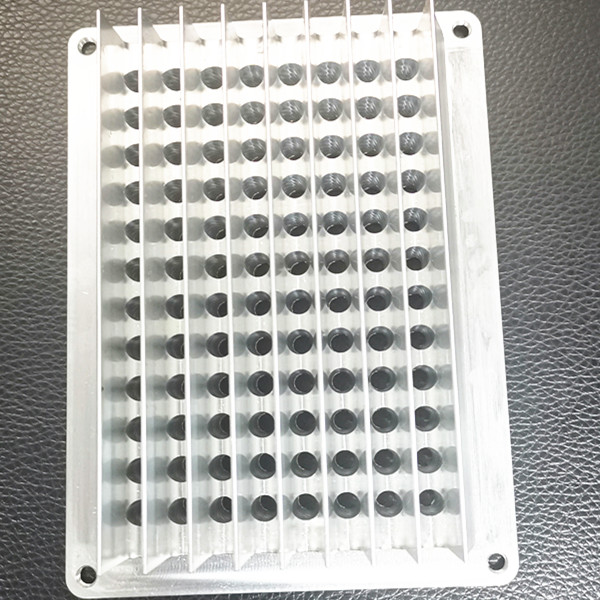

Machining and Assembly Part – Electronic product installation fixture

Material: Aluminum 6061/7075

Application: Electronic equipment-The heat sink is used for the heat dissipation of the PCB board, power supply cabinet, and high-power LED lamps.

Description:

Accuracy: True position 0.02mm

Surface Treatment: Clear Anodized

Main Process: CNC machining Service

Machining Part-Mechanical equipment shaft

Material: Stainless steel 303/304/316L/Brass

Application: Mechanical equipment

Description:

Process: Turing&Grinding

Weight: 2.3kg

Accuracy: Internal diameter tolerance 0.01mm